Sewing machines are complicated pieces of kit, and many things can go wrong with them if you are not careful. Whether you are simply threading your machine to using it to create a beautiful quilt, knowing to how fix simple complications is of the utmost importance.

One problem that every sewer has probably come across is the needle of the sewing machine not picking up the bobbin thread. You must have thread feeding properly from the bobbin in order to create stitches, so if this is happening to your machine, it is important to remedy the situation as you will not be able to sew.

There are a few aspects of your sewing machine to check on if you notice that your bobbin thread is not being picked up by your sewing machine.

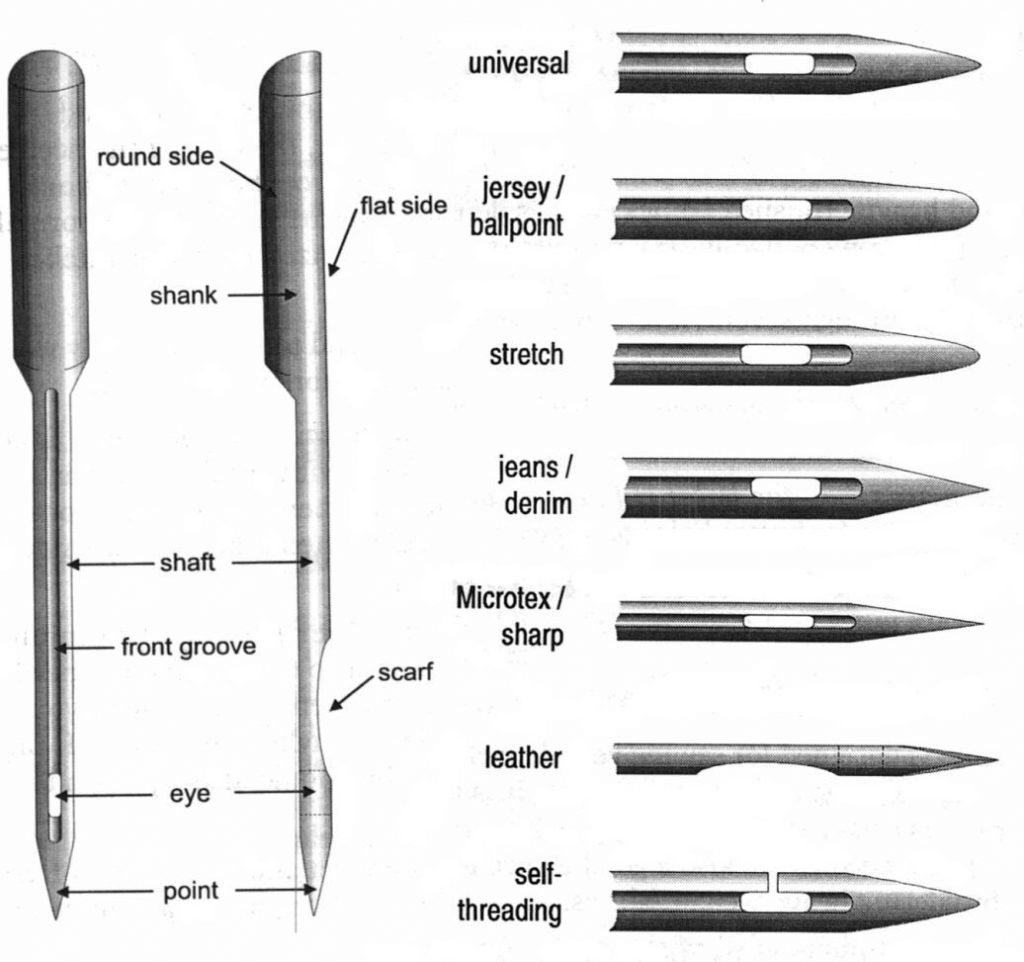

Your bobbin could be malfunctioning due to the needle you are using.

First, make sure that the needle you are using is appropriate for the fabric type you are sewing with. For example, light fabrics need different needles than heavy duty fabrics like leather or denim do.

Once you determine that you are using the correct needle for the fabric type you are working with, ensure that it is not bent or broken.

If you have not correctly threaded your machine to begin with, this could lead to problems with the bobbin.

Threading the bobbin itself or inserting it into the machine could also be a problem. Consult your user manual and make certain that you are doing both of these items correctly.

Remember, before you begin sewing, your needle thread and bobbin thread should be resting on top of the throat plate. The throat plate refers to the flat piece of metal that is located below the presser foot.

When threading the sewing machine, make sure that the thread remains at the proper tension level. If one part of your sewing machine creates too much tension on the thread, it will not be able to pass freely through the machine and it will most likely break.

If you seem to be having tension issues with your sewing machine, try changing out the tension discs. Having good tension discs is the best way to deftly control the thread tension while sewing.

You can also adjust the tension in the bobbin thread. In order to do this, you need to slightly adjust the tension screw.

The tension screw is the largest screw in the bobbin case. Typically, you should not need to adjust the bobbin thread tension, but you might need to depending on what type of thread you are sewing with.

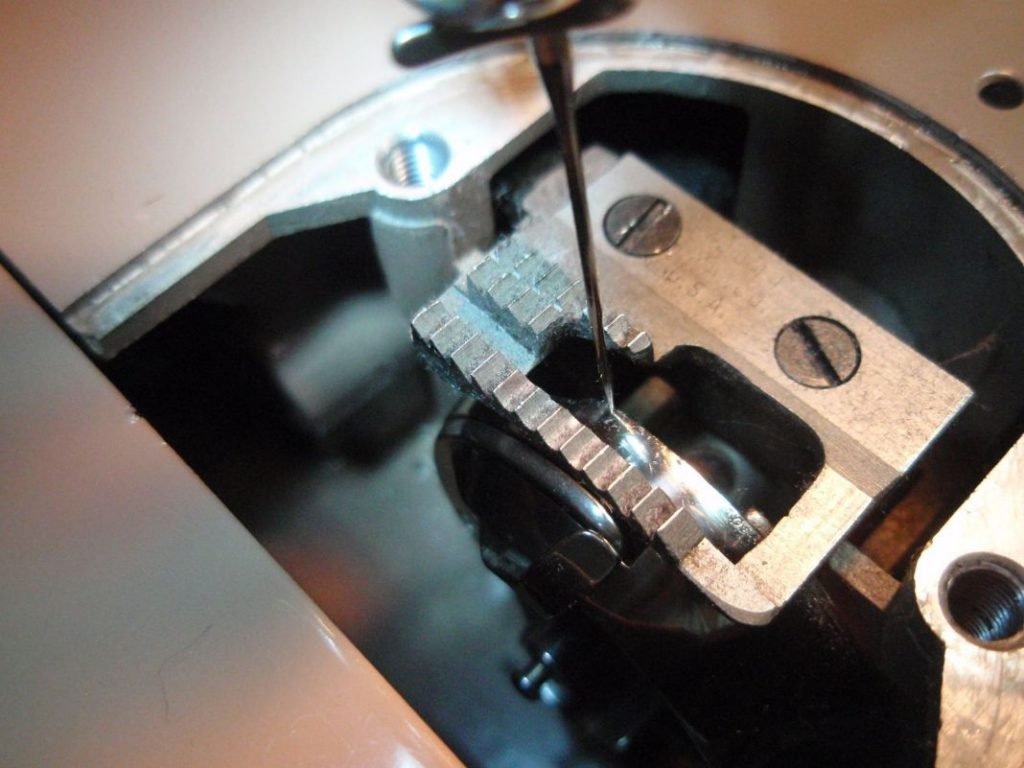

One issue that is messing with the bobbin thread could be that dirt and debris have collected inside your sewing machine. If you suspect this could be the cause of your problems, clean the shuttle area of your sewing machine.

In order to do this, remove the bobbin shuttle and bobbin case from the body of the sewing machine. Consult your user manual often to ensure that you do not accidentally break anything.

Remove any lint, thread and fabric debris, and dust from the shuttle area. A clean machine is a better working machine after all.

Carefully clean underneath the bottom of the feed dogs. Finally, reassemble and rethread your sewing machine.

Cleaning out the shuttle area of your is a good practice to make routine, as it will prolong the life of your sewing machine.

Your bobbin may not be catching the thread because the timing of your sewing machine could be off.

If the timing of your machine is off, the needle and the bobbin will not be in position at the same time, and a stitch will not be formed.

You can tell if you are having timing issues if the hook tip from the bobbin is not passing through the loop that the needle creates.

Timing issues on sewing machines are tricky to solve alone. If this is the case, you may need to take your machine to be serviced by a professional.

It is much easier to fix the bobbin thread yourself if you know what it is used for in the first place.

A Sewing machine makes stitches by locking two threads together through the fabric that you feed through it. The threads come from the top thread, fed over the body of the sewing machine and from the bobbin, in the base of the machine.

If your bobbin thread is not being picked up by the machine, then you will not be able to actually create any permanent stitches in your fabric.

Another common bobbin problem that many sewers face is when the sewing machine needle actually hits against the bobbin case. If this happens, the needle can break.

The most common reason that your needle may be hitting the bobbin case is that the bobbin case has not bee placed correctly. If you have just cleaned your sewing machine, double check to see if you have put everything back in its proper place.

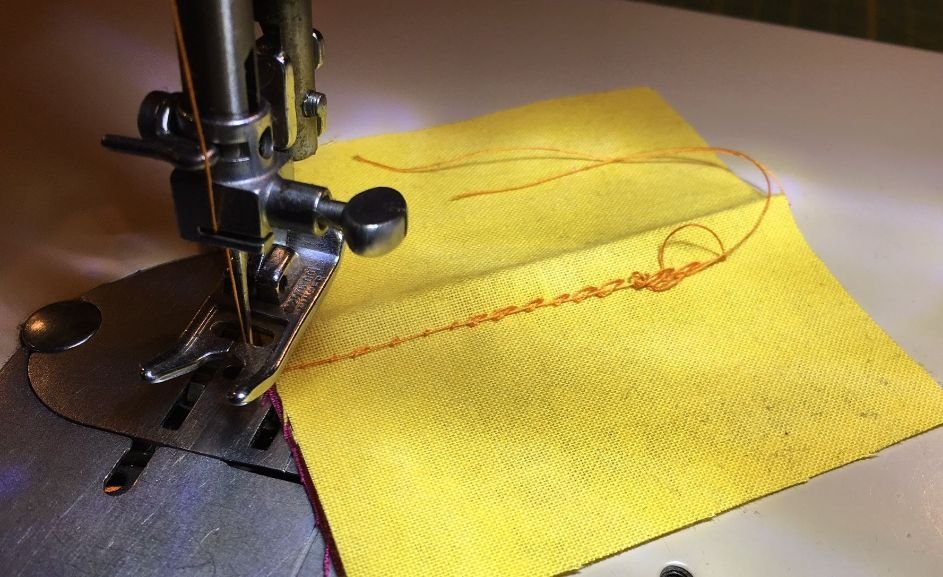

Bunching thread from the bobbin is another problem that could happen with your sewing machine. If this is happening, it is almost always a thread tension issue.

If your thread is looping underneath from the bobbin, then your top tension is too loose in comparison to the bobbin tension.

Always adjust the top tension before you adjust the bobbin tension. Most commonplace tension issues can be solved by simply playing with the top bobbin tension.

If the top tension is already rather tight, now you should adjust the bottom tension from the bobbin.

The best way to deal with bobbin issues is to avoid them altogether in the first place. Follow these few helpful rules to make using your sewing machine a less frustrating experience.

Bobbin complications are some of the most common problems that DIY sewers face on a regular basis while using their sewing machines. Improper threading of the machine is the main reason for a bobbin not catching its thread.

If you follow the tips and tricks in this article, however, you should be able to fix most bobbin problems you come across and hopefully, avoid most of those problems altogether.

Happy sewing!