Even if you are an advanced sewer for many years, you can still run into problems during the sewing process, leaving you frustrated as to why your machine can't move the fabric.

The most common reason as to why your sewing machine can't move fabric has to be the feed dogs which might be too far down or worn, the threading itself, bobbin thread tension or the size of your stitch length.

So to find out what is causing your sewing machine to not move fabric when you try and sew, we have put together a small guide below which will cover the common causes, allowing you to troubleshoot and fix your machine.

As we touched on above, at any time sewing, you can run into problems with your machine, and one of them can be that they won't be able to sew/move the fabric.

We have listed out the common sewing machine problems that cause this issue down below.

The feed dogs are the part of your sewing machine which are located below the sewing machine needle and presser foot. It's what feeds the fabric through the machine when sewing, so when these get worn out, they are no longer sharp enough to feed and must be replaced.

Feed dogs can additionally be positioned too far down which will stop them from feeding properly, to fix this all you need to do is raise them back up again.

If your feed dogs are jammed then dust could be the reason, luckily to remedy this all you need to do is some cleaning around the area and lubricate.

No matter how experienced you are, it is still possible to thread your sewing machine incorrectly, this improper thread will not move the fabric, but the best way to fix this is just by rethreading the machine.

A tangled thread with a knot cab also get caught in the tension discs of your machine causing it not to move the fabric.

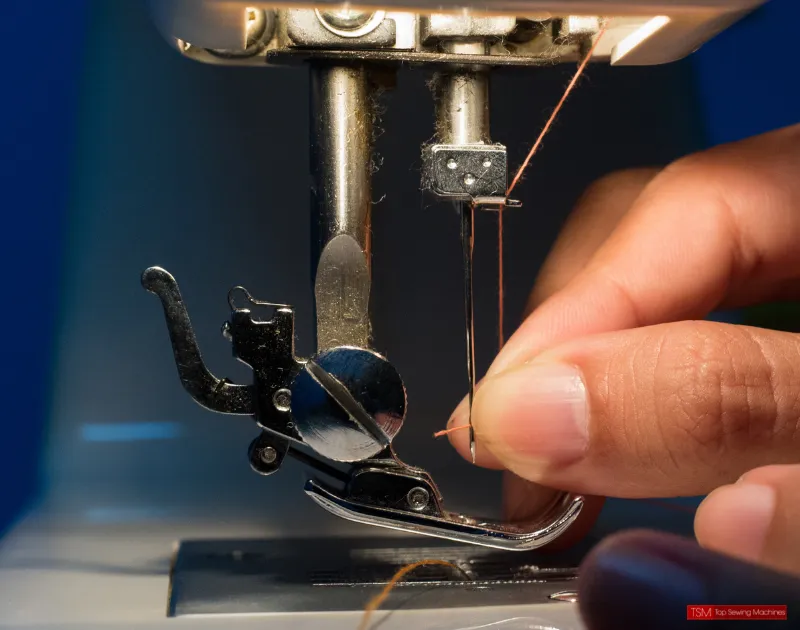

To thread your machine sewing properly, make sure your thread take-up lever is in the highest position, attach the spool of thread then pull it through the tension discs and thread guides according to your sewing machine manual.

Pull your thread through the eye of the needle leaving a four-inch tail.

Different sewing machines will have a variety of stitch lengths between 0-7mm, this determines how much it will pull the fabric when sewing. If your fabric is not moving then your single stitch length could be set to zero which happens after making stitches such as an automatic buttonhole stitch.

Simply adjust the sewing machine from the lowest stitch to a higher length and see if it solves the problem.

A very tight upper thread tension can stop the fabric from moving through your machine. It's important to make sure the bobbin and thread have the same weight of tension according to the material that you are sewing.

Don't make a habit of changing your bobbin tension too much, instead, loosen the upper thread by turning the tension dial on your machine counterclockwise.

The more layers that pass through your machine when sewing the harder it is to sew as the fabric becomes too thick.

There are two ways you can try and fix this if your fabric is not moving, either reduce the layers in your machine or instead try sewing at a slower speed to stop it from snagging and getting stuck.

A presser foot on your machine that is left up can stop the fabric from moving through your machine as the feed dogs will not have any grip on the fabric. This is a common sewing mistake on older machines as they don't warn you when the presser foot is left down.

Always try and check everything before starting sewing projects to prevent this from happening in the future.

It is inevitable that overtime sewing your bobbin case will build up with lint from the threading, this can potentially jam up your sewing machine and stop the needle from moving forward, therefore stopping the fabric from moving forward too.

Make sure you are cleaning and maintaining your sewing machine to avoid this.

When working with thick material or at a fast stitch pace, your sewing machine may become overworked and therefore overheat, allowing your model to cool down before trying to stitch again will solve the problem.

My fabric has been pulled inside of my machine, what should I do?

If your fabric has somehow entered your machine then you will need to turn off the machine, remove the presser foot and holder then cut the thread below the fabric. Never try and pull the fabric outside as this force can damage it.

What are other common problems in sewing machines?

Some other common issues are motor problems, thread snapping or tension problems.

How do I maintain my sewing machine?

To maintain your sewing machine you should be changing your needle after every 8 hours of use, wiping it down, keeping it covered from dust when not in use and brushing debris from its moving parts often.

You should also be oiling your machine according to the manual that comes with the model.

Why is my machine pulling fabric inside?

If your sewing machine is pulling fabric inside then your needle and fabric might not match, always replace a damaged, bent or blunt need before trying to sew as these can hit the feed dogs and cause the fabric to be moved in the wrong direction.

What should I do if my fabric is too thick for my sewing machine?

First off, try and switch to a thinner fabric if you can, but if not then a roller foot or a walking foot may help you sew with the machine. Thick fabric can stop your sewing machine from moving so you should never force it but instead, work at a slower speed.

To conclude, if your sewing machine is not moving fabric then it is likely down to the feed dogs, bad threading, too tight tension or the fabric is too thick, all of these issues can be solved with ease with our troubleshooting guide above.

Never pull or force fabric through the machine if it gets stuck and doesn't move, always refer to your manual and turn off the machine instead then proceed.